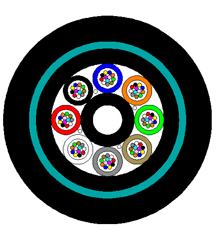

GYTY53

The GYTY53 Outdoor Direct Buried Fiber Optics Cable are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire sometimes sheathed with polyethylene (PE) for cable with high fibre count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. The cable core is filled with the filling compound to protect it from water ingress, over which a thin PE inner sheath is applied. After the PSP Is longitudinally applied over the inner sheath, the cable is completed with a PE outer sheath.

1.Good mechanical and temperature performance

2.High strength loose tube that is hydrolysis resistant

3.Special tube filling compound ensure a critical protection of fiber

4.Crush resistance and flexibility

5.PE sheath protects cable from ultraviolet radiation

6.Steel wire used as the central strength member

7.Loose tube filling compound

8.100% cable core filling

9.PSP enhancing moisture-proof,APL moisture barries

10.Water-blocking material

| Min Bending Radius(mm) | Long term | 10D | |||||

| Min Bending Radius(mm) |

Short term | 20D | |||||

| Min allowable Tensile Strength(N) |

Long term | 1000 | |||||

| Min allowable Tensile Strength(N) |

Short term | 2000 | |||||

| Crush Load (N/100mm) | Long term | 1000 | |||||

| Crush Load (N/100mm) | Short term | 2200 | |||||

| Operation temperature (℃) |

-20+70 | ||||||

| Installation temperature(℃) |

-20+60 | ||||||

Other Products

-

Indoor FTTH Fiber Drop Cable

Indoor FTTH flat drop cable or bow-type drop optical cable are used for last mil -

Outdoor FTTH Flat Drop Cable

Outdoor Self-supported FTTH flat drop cable are used in high speed and broadband -

Indoor Distribution Fiber Cable

Distribution cable is tight buffered and no electrical conductive components des -

Indoor Breakout Fiber Cable

The Breakout fiber cable is consisted with a FRP surround by a number of jackete -

Flat Twin Ruggedized Duplex Fiber Cable

Flat twin ruggedized duplex fiber optic cable is constructed with two tight buff -

Indoor Ribbon Flat Fiber Cable

Indoor Ribbon Flat Fiber Cable is with a layer of aramid yarn as strength member -

Duplex Round Far Transmission Cable

The duplex round far transmission cable is with 2.0mm simplex sub-unit.mainly u -

Ultra Light Armored Fiber Cable

Ultra Light armored fiber cable is designed for harsh environment quick field in -

Tight Buffered Micro Round Drop Cable

Micro ADSS Optical Drop cable consists of individually colour coated 250um fiber -

Dual Jacket ADSS Fiber Cable

ADSS (All Dielectric Self-Supporting) cable is nonmetallic fiber cable to be ins -

12C MINI ARMORED FIBER CABLE

The 12mini armored fiber cable is specially designed for the MPO/MTP connectors -

Indoor Outdoor Non-armored Loose Tube Ca

The indoor and outdoor fiber optic cable is designed with one high modulus loose -

E-Glass Yarn Anti Rodent Figure 8 Fiber

The fiber cable consists of loose fiber tube which made of high modulus plastic -

FTTH Aerial Drop Cable

This FTTH cable structure is with figure 8 structure with steel messenger, kelva -

ADSS FIBER CABLE SINGLE JACKET

ADSS (All Dielectric Self-Supporting) cable is non metallic fiber cable to be in -

Optical Fiber Power Composite Cable

Optical fiber power composite cable is applicable to transmission line in broadb -

Mini Loose Tube Indoor Fiber Cable

The mini loose tube indoor fiber cable is 2-24 fiber surrounded by kelvar with o -

AIR BLOWN MICRO UNITUBE CABLE

Air blown micro unitube cable is ultra lightweight in small diameter to be blown -

AIR BLOWN PE MICRO FIBER CABLE

Micro air blown fiber optic cable, big fiber counts in smaller diameter is mainl -

Indoor Outdoor 96C Armored Fiber Cable

Features: –Mini diameter SUS spring tube reinforced ensure good mechanical -

GYTDA RIBBON OUTDOOR CABLE

GYTDA belongs to optical ribbon cable which featured with intensive fiber, small -

Aerial Self-Supported ASU Fiber Optic Ca

ASU cable is also known as Mini ADSS optical fiber. It is a kind of optical cabl -

Invisible Fiber Optic Drop Cable

The Invisible Fiber Optic Drop Cable provides best solution without impacting on